Series 1206 VIBRAPLANE Isolation Mounts

If you are designing, retrofitting, or upgrading a wafer scanner, substrate defect inspection tool, or any number of other semiconductor processing, inspection, or packaging tools, chances are you need vibration control. Our Series 1206 Vibration Isolation Mounts provide the same legendary VIBRAPLANE™ performance and reliability as our workstations and optical table systems and can be readily configured to match the precise specifications of your application or design.

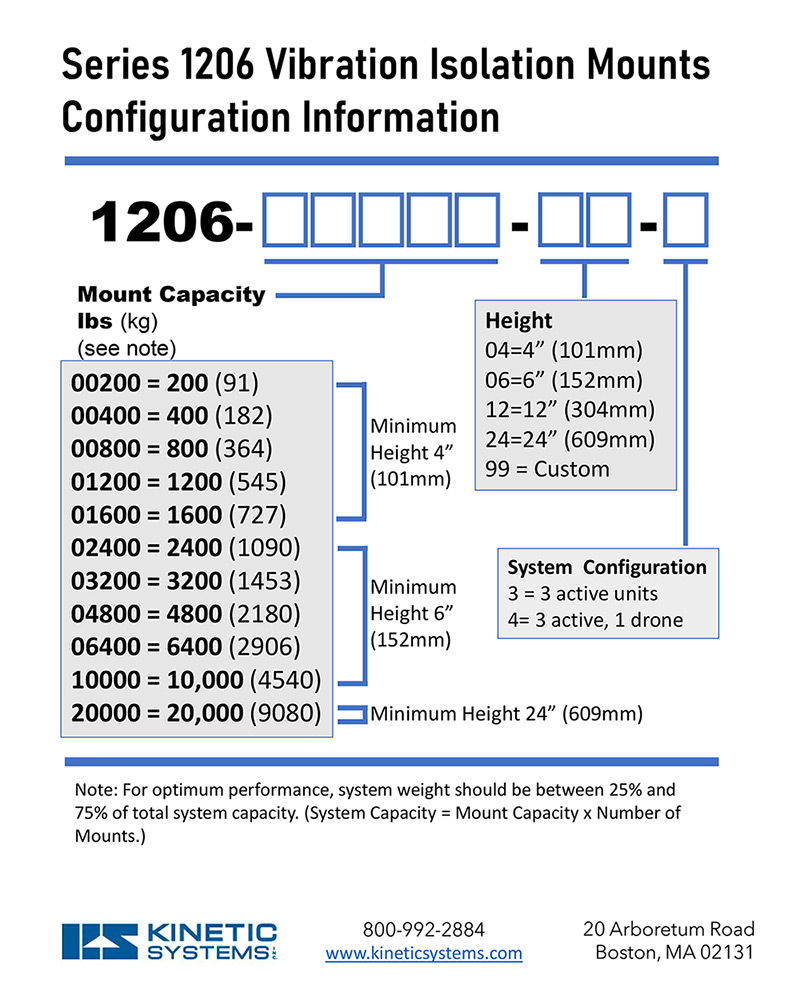

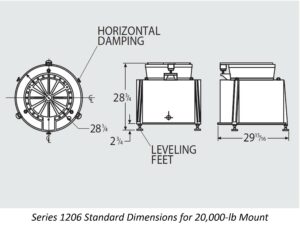

Series 1206 Vibration Isolation Mounts are available in passive or Active-Air configurations and may be used individually or in sets of 3, 4, 6, or more mounts. Choose from tig-welded aluminum or steel construction, load capacities from 200 to 20,000 pounds, and operating heights as low as 4.25”. Systems may be designed to include an ultra-light breadboard or inertia-mass platform of virtually any shape or size. Vacuum-compatible, non-magnetic, and specialty materials are common features of our custom and OEM products. Our Series 1206 Vibration Isolation Mounts are relied upon by large and small semiconductor processing equipment manufacturers, and they can be found in wafer fabs all around the world. Contact our engineers today to learn more about how our Series 1206 Vibration Isolation Mounts can help you to improve the speed, accuracy, and repeatability of your semiconductor processing or inspection tool.

Active-Air Vibration Control

Series 1206 Vibration Isolation Mounts are offered in active and drone configurations. Active mounts use our VibraLevel air servo valves with a compressed air source to “feed” or “bleed” air to or from each mount, ensuring near-zero net displacement even when subjected to a changing load. Drone mounts do not have air servo valves, but instead are controlled by an active mount. Because three points are needed to define a plane, each system typically utilizes three active mounts, with the total number of drones dependent on load and configuration.

Tailor-made to your exacting specifications

In addition to load, height, and other options discussed above, each mount can be customized with base plates and top plates of any shape or hole configuration. Center-to-center mounting hole locations are guaranteed to be within 0.001” so you can be sure your mounts will fit right, every time.

Cleanroom-Compatible

Our Series 1206 Vibration Isolation Mounts can be manufactured for Class 1, Class 10, and Class 100 cleanrooms and have become standard equipment in wafer fabs throughout the industry.

Add a Breadboard or Inertia Plate

Our Series 1206 Vibration Isolation Mount systems are fully customizable and can include a dedicated rigid platform if needed. Whether one of our light, rigid, and ultra-flat VibraLite breadboards, or a cradle-style inertia mass welded from sold steel, our engineers will work with you to specify the optimal vibration control solution for your unique application.

- Low natural frequency

- Automatic leveling and height control, within .005″

- Vertical and horizontal isolation

- Internal damping for improved stability

- Gross loads: 200 to 20,000 lbs.

- Four standard heights

- Custom heights and configurations for OEM applications

- Class 100 Cleanroom Compatible – Class 10 available

1206 Series

Square Mount Interface Dimensions – in (mm)

Steel Construction, 200-3200 lbs

| Model No. |

A |

B |

C |

D* |

E |

F |

| 1206-00200-24 |

7.00 (178) |

5.50 (140) |

4.75 (121) |

.31 (7.9) |

4.50 (114) |

4.50 (114) |

| 1206-00400-24 |

7.00 (178) |

5.50 (140) |

4.75 (121) |

.31 (7.9) |

4.50 (114) |

4.50 (114) |

| 1206-00800-04 |

8.50 (216) |

6.50 (165) |

5.50 (140) |

.38 (9.6) |

5.50 (140) |

6.00 (152) |

| 1206-00800-06 |

8.50 (216) |

6.50 (165) |

5.50 (140) |

.38 (9.6) |

5.50 (140) |

6.00 (152) |

| 1206-00800-12 |

8.50 (216) |

6.50 (165) |

5.50 (140) |

.38 (9.6) |

5.50 (140) |

6.00 (152) |

| 1206-00800-24 |

8.50 (216) |

6.50 (165) |

5.50 (140) |

.38 (9.6) |

5.50 (140) |

6.00 (152) |

| 1206-01200-04 |

8.50 (216) |

7.50 (191) |

6.50 (165) |

.38 (9.6) |

5.50 (140) |

6.00 (152) |

| 1206-01200-06 |

8.50 (216) |

7.50 (191) |

6.50 (165) |

.38 (9.6) |

5.50 (140) |

6.00 (152) |

| 1206-01200-12 |

8.50 (216) |

7.50 (191) |

6.50 (165) |

.38 (9.6) |

5.50 (140) |

6.00 (152) |

| 1206-01200-24 |

8.50 (216) |

7.50 (191) |

6.50 (165) |

.38 (9.6) |

5.50 (140) |

6.00 (152) |

| 1206-01600-04 |

8.50 (216) |

7.50 (191) |

6.50 (165) |

.38 (9.6) |

5.50 (140) |

6.00 (152) |

| 1206-01600-06 |

8.50 (216) |

7.50 (191) |

6.50 (165) |

.38 (9.6) |

5.50 (140) |

6.00 (152) |

| 1206-01600-12 |

8.50 (216) |

7.50 (191) |

6.50 (165) |

.38 (9.6) |

5.50 (140) |

6.00 (152) |

| 1206-01600-24 |

8.50 (216) |

7.50 (191) |

6.50 (165) |

.38 (9.6) |

5.50 (140) |

6.00 (152) |

| 1206-02400-06 |

9.75 (248) |

8.50 (216) |

7.56 (192) |

.38 (9.6) |

6.00 (152) |

7.00 (178) |

| 1206-02400-12 |

9.75 (248) |

8.50 (216) |

7.56 (192) |

.38 (9.6) |

6.00 (152) |

7.00 (178) |

| 1206-02400-24 |

9.75 (248) |

8.50 (216) |

7.56 (192) |

.38 (9.6) |

6.00 (152) |

7.00 (178) |

| 1206-03200-06 |

10.75 (273) |

10.00 (254) |

9.00 (229) |

.50 (12.7) |

6.50 (165) |

8.00 (203) |

| 1206-03200-12 |

10.75 (273) |

10.00 (254) |

9.00 (229) |

.50 (12.7) |

6.50 (165) |

8.00 (203) |

| 1206-03200-24 |

10.75 (273) |

10.00 (254) |

9.00 (229) |

.50 (12.7) |

6.50 (165) |

8.00 (203) |

* Diameter of Baseplate Mounting Hole

1206 Series

Round Mount Interface Dimensions – in (mm)

Aluminum Construction, 200-10,000 lbs

| Model No. |

A |

B |

C |

D |

E |

F |

| 1206-00200-04 |

– |

3.50 (89) |

2.75 (70) |

.25 (6.3) |

– |

– |

| 1206-00200-06 |

– |

3.50 (89) |

2.75 (70) |

.25 (6.3) |

– |

– |

| 1206-00200-12 |

–

|

3.50 (89) |

2.75 (70) |

.25 (6.3) |

–

|

–

|

| 1206-00400-04 |

– |

4.50 (114) |

3.50 (89) |

.31 (7.9) |

– |

– |

| 1206-00400-06 |

– |

4.50 (114) |

3.50 (89) |

.31 (7.9) |

– |

– |

| 1206-00400-12 |

–

|

4.50 (114) |

3.50 (89) |

.31 (7.9) |

–

|

–

|

| 1206-04800-06 |

13.50 (343) |

10.50 (267) |

9.00 (229) |

.62 (15.7) |

8.25 (209) |

10.50 (267) |

| 1206-04800-12 |

13.50 (343) |

10.50 (267) |

9.00 (229) |

.62 (15.7) |

8.25 (209) |

10.50 (267) |

| 1206-04800-24 |

13.50 (343) |

10.50 (267) |

9.00 (229) |

.62 (15.7) |

8.25 (209) |

10.50 (267) |

| 1206-10000-06 |

19.00 (483) |

16.00 (406) |

13.00 (330) |

.75 (19.0) |

11.00 (279) |

16.00 (406) |

| 1206-10000-12 |

19.00 (483) |

16.00 (406) |

13.00 (330) |

.75 (19.0) |

11.00 (279) |

16.00 (406) |

| 1206-10000-24 |

19.00 (483) |

16.00 (406) |

13.00 (330) |

.75 (19.0) |

11.00 (279) |

16.00 (406) |

Performance Data – 1206 Mounts

| Min. Load @ 20 psi | |

| Vertical Natural Frequency | 3.0 Hz |

| Isolation Efficiency @ 5 Hz | 40% |

| Isolation Efficiency @ 10 Hz | 90% |

| Horizontal Natural Frequency | 3.5 Hz |

| Isolation Efficiency @ 5 Hz | 35% |

| Isolation Efficiency @ 10 Hz | 80% |

| Max. Load @ 80 psi | |

| Vertical Natural Frequency | 1.5 Hz |

| Isolation Efficiency @ 5 Hz | 89% |

| Isolation Efficiency @ 10 Hz | 97% |

| Horizontal Natural Frequency | 2.1 Hz |

| Isolation Efficiency @ 5 Hz | 78% |

| Isolation Efficiency @ 10 Hz | 94% |

| Finish | |

| Standard | Blue Polyurethane |

| Class 10 | White Epoxy Powder Coat |

Note: Typical performance efficiencies are for microdisturbances.

Talk with one of our experts about your project needs today!

Customers often come to us with tough vibration problems for which they can’t find an off-the-shelf solution. Solving these challenges is at the heart of what we do here at Kinetic Systems. Contacting us early on in your project yields the best results. What are your unique vibration challenges? Tell us a little bit about your project in the form below. We’ll be in touch within one business day with suggestions for how we can help!